01

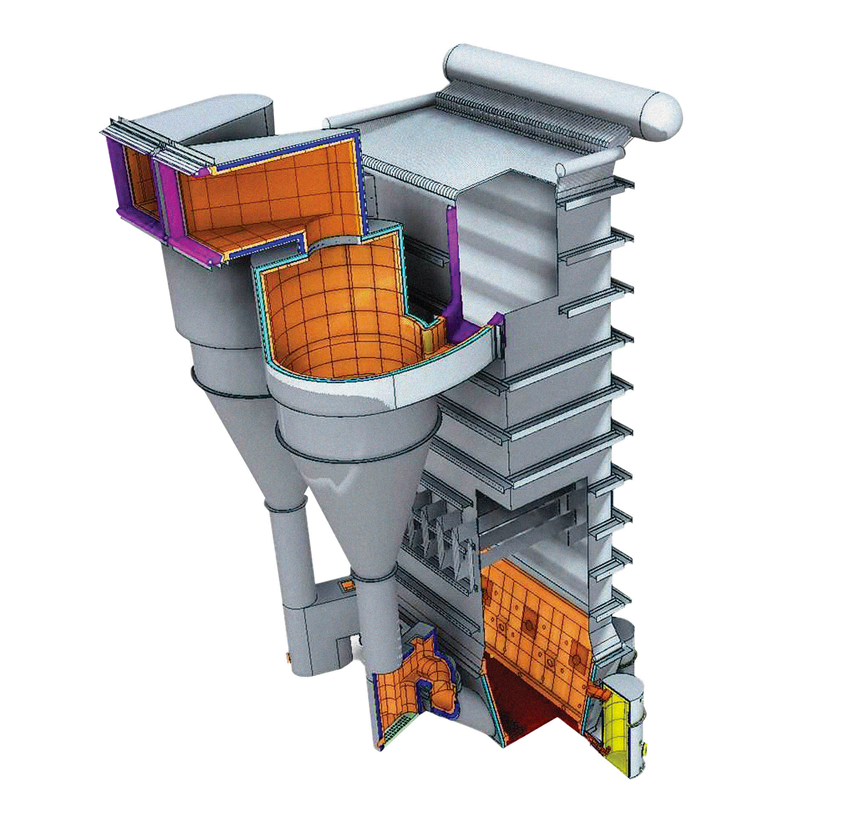

Linings for industrial boilers

For the design and assembly of boiler liners, factors such as the chemical composition of the combustion medium in response to high temperature, flue gas in the unit under full operation, the frequency and duration of shutdowns, the burner technology (hot air flow), the static and moving parts of the boiler, the required temperature on the outside of the steel structure and other matters are decisive.

Appropriate selection of linings and their installation into boilers can save up to 35 % of the normal costs of repairing the internal insulation of the steel structure. This, of course, has a significant impact on the boiler operation, hence the financial return from it.

Linings for industrial furnaces

For furnaces, decisive factors for the design and assembly of furnace linings include the chemical composition of the melt/batch, including their additives in response to high temperature, mechanical movement in or with the furnace, frequency and duration of shutdowns, burner technology (hot air flow).

Appropriate selection of linings and their installation into furnaces can save up to 25 % of the normal costs of repairing the internal insulation of the steel structure.

We prepare the projects in advance, with thoroughness in their organization, and in the drawing documentation. That is why we are able to execute the building part of the project on time, precisely, and to the agreed quality.

02