AL INVEST Břidličná a.s.

General repair of linings for TLA 15 furnace, general repair of linings for KONTI furnace, repair of linings of KONTI furnaces during summer and winter shutdowns, incl. materials supply and project documentation. For general repair of furnaces, DITHERM proposed a new lining concept (chemically bonded materials), thanks to which we made it possible to shorten the general repair time by approx. 40 %. Furthermore, the materials used by us eliminate the growth of “stuccoes” in fixation furnaces and allow for so-called quick repairs (including torkreting) to be carried out, i.e. after the repair, it is possible to almost immediately carry out the “start-up” of the furnace for regular operation.

From 2011 to date

Benteler Automotive Malacky SK

Repair of linings of annealing roller furnaces, incl. supply of materials

This is a service repair of liners, with our arrival within 72 hours of being called by the customer.

In 2014, 2015

Benteler Automotive Rumburk

Repair of linings of annealing roller furnaces, incl. supply of materials

This is a repair of linings, with our arrival within 72 hours of being called by the customer. During these repairs, we innovate the lining, for example, a complete floor replacement for the furnace, where a new concept of furnace flooring was used from Benteler Maschinenbau

From 2014 to date

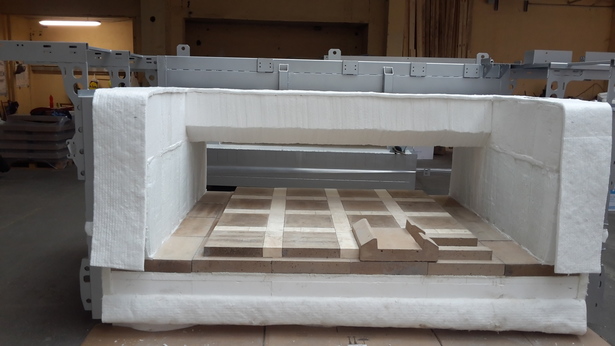

Benteler Maschinenbau CZ, s.r.o. - lining assembly

Year-round installation of refractory linings for at least 40 pcs of annealing roller furnaces for the automotive industry, including the supply of materials and design documentation. The furnaces are always new, and are produced at the request of the investor in different countries. Installation requires special skills when changing individual details.

2008 – present

Benteler Maschinenbau Liberec

Assembly of linings of annealing roller furnaces, incl. the supply of materials and project documentation in the construction of new roller annealing furnaces. This is a long-term co-operation project. At the beginning, DITHERM participated in the development and design of linings for these furnaces. The furnace lining passes through constant innovations and improvements, where incentives come from the end customers, literally from all over the world, where the furnaces are built.

From 2008 to date

Cemex Cement (previously Holcim Prachovice)

DITHERM has organised repairs to the rotary kiln heat exchanger, repairing the damaged sloping roof on the radiator grille, complete repair of the base piece during overhaul and repairs of linings under the clinker cooler.

DITHERM has increased the lifetime of linings that the alkaline environment of alternative fuels uses.

During the period from 2010 to 2013

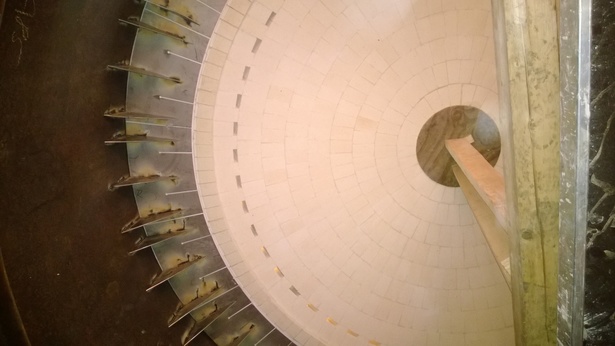

Českomoravský cement, a.s., nástupnická společnost, závod Mokrá a Radotín

DITHERM has been providing and carrying out long-term service and repair of refractory linings of rotary kiln production lines, especially for common repairs of heat-head linings and heat exchangers of rotary kilns and clinker coils, for many years.

Among other things, we performed casting of burners and burner tips. We have achieved excellent results, mainly in general repairs of internal heat-resistant insulation, especially in the quality and organization of work, which were decisive for the timely roll-up of the aggregate and its subsequent fault-free operation.

2004–2010

Kovohutě Rokycany

Repair of refractory linings on AJAX, WSW, TG, KOPP melting aggregates. Repairs of annealing chambers and deep-furnaces, including related activities, incl. project documentation of linings.

Co-operation takes place under the so-called service agreement, with our arrival within 48 hours of being called by the customer.

From 2009 to date

PEWAG

General repair of linings for 2 hinged annealing furnaces RHG 2000/3250. Design, project documentation, delivery and installation of insulating linings.

No project documentation was available for the furnaces. The design and technical team of DITHERM had to measure, design and think up new designs.

In 2013

Precheza – Condensation tower

Design, delivery and installation of acid-proof insulations and linings.

Design, delivery and installation of the lining of the internal support for the storage of the reaction charge.

Supply and storage of the reaction tower - raschig rings.

DITHERM has proposed a new concept of acid-proof linings and insulation, based on foam glass, which has enabled (where the inlet gas temperature is 320 °C) their use to protect the steel structure before acidic rubber coating.

In 2016

PRECHEZA, a.s. – Condensation tower ŽPM

This is a new lining concept using modern lining materials. We designed a liner that is more environmentally friendly and less risky, from the point of view of work safety, when installing it, than the original lining. In 2015 - design, in 2016 - implementation

RONA a.s. Lednické Rovne

Glasswork baths TA1, TA2, TA3, TA5 - made by the subsidiary, Termostav.

SITA CZ

Replacement of the lining of the rotary kiln at the Ostrava incinerator, inc. supplies of materials and project documentation

In 2013, 2014

SORG GmbH & Co. KG (Germany)

Lining of glassworks regenerators - realized by the subsidiary, Termostav.

Synthesia

GENERAL REPAIR of lining for combustion furnace and steam boiler at position N8, incl. material delivery, project documentation and execution of lining tempered to 300 °C by external sources. This was an emergency repair, with the fact that only 3 weeks had elapsed from the customer’s call until the start of the event, during which time we managed to provide approx. 35,000 pieces of acid-resistant and insulating form material to design the project documentation, and to provide logistics and personnel for the entire construction. We realized the project in a record time of 24 calendar days.

R. 2013

UNEX Uničov

Melting plant - year-round service of refractory linings, incl. supply of materials and design documentation (EOP, pouring pans, induction furnaces, stoppers, Ar nozzle delivery, etc.).

DITHERM significantly increased the life of the linings. An important role in such furnaces is the ability of the team to work well and to be professional, as it is inevitable to respond to the unexpected outages of the furnace.

From 2003 to date

UNEX Uničov

Finishing + tempering workshop - year-round service of refractory linings, incl. supplies of materials (hardening furnaces, annealing furnaces, furnace trucks, etc.).

We have increased the lining life. An important role in such furnaces is the ability of the team to work well and to be professional, as it is inevitable to respond to the unexpected outages of the furnace.

From 2003 to date